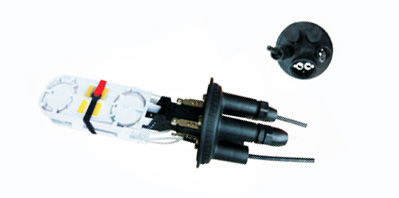

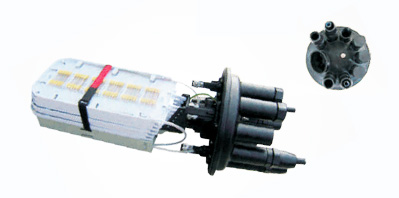

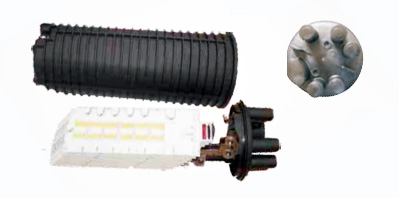

Dome type optical splice closures are used to distribute, splice, and store the outdoor optical cables which enter and exit from one (same) end of the closure. There are two connection ways: direct connection and splitting connection. They are applicable to situations such as overhead, manhole, embedded situation etc. Most dome closure can fit numerous fiber connections. They are designed to be waterproof and dust proof. They can be used in temperature ranging from -40°C to 85°C, can accommodate 70 to 106 kpa pressure and the case are usually made of high tensile construction plastic.

D-CONNECT Dome closures are designed for use with any cable construction (loose buffer tube, central core tube, loose fiber, and ribbon), in any environment (aerial, pedestal, buried, handhole, and manhole), and for numerous splice applications (express, tap-off, branch, and repair.

PUNCTILIOUS Quality Control

We understand that a company's investment in structured cabling and fibre solutions is expected to fetch a long-term return, hence, we have a dyed in the wool policy for quality testing. We are committed to use only the best material and always exceed customer's expectations in terms of standard.All our products areROHS compliant and manufactured under a great degree of supervision and stringent in-process inspection.

Each of the manufacturing and assembly units is ISO 9001:2015 and ISO 14001:2015 certified.Strict qualification and evaluation of designs, material and processing methods ensure guaranteed customer satisfaction. Once manufactured, the products are sent to the QA team where each and every technical specification is checked and tested in detail.

A robust corrective auto-system is in place with firm focus on verification for troubleshooting.

Sign up to our newsletter and be the first to know about latest news, special offers, events, and discounts.

© 2018 All Rights Reserved. Terms of Use and Privacy Policy