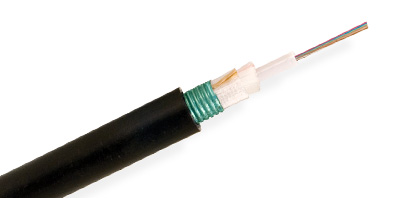

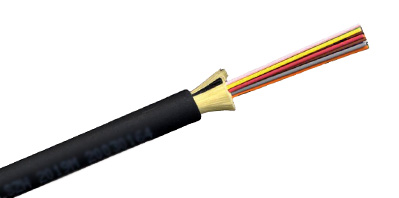

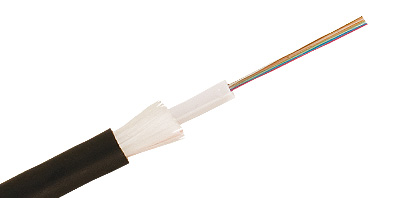

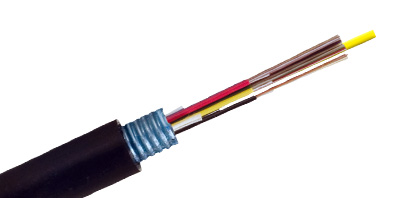

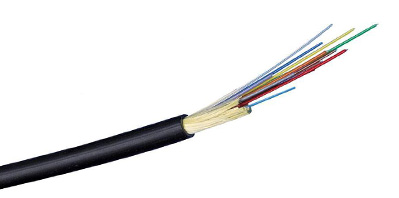

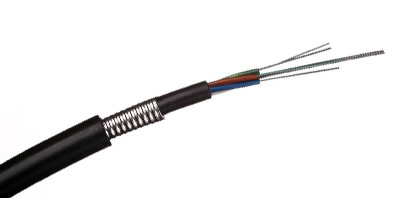

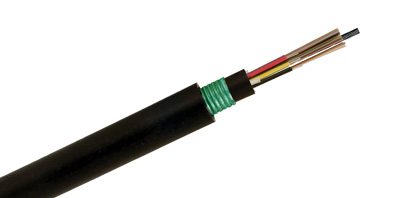

A fiber optic cable configuration involving a semi-rigid hollow plastic tube that houses and protects a number of optical fibers. The fibers can be either individually coated or organized into ribbons coated with protective acrylate and the tube is flooded with a water blocking gel. The tube or tubes are then helically stranded around a dielectric (e.g., fiberglass) or steel central strength member that supports the handing weight of the cable and prevents buckling. There also commonly is an aramid yarn strength member in the cable core. An outer polyethylene jacket surrounds the entire cable. If armoring is required for protection from rodents and other critters, a metallic tape or mesh is formed around the jacket and another jacket is formed to surround the armoring. Loose-tube cable is used in outside plant (OSP) applications, where extremes of temperature, rough handling, and mechanical disturbances make tight buffered cable unsuitable.

PUNCTILIOUS Quality Control

We understand that a company's investment in structured cabling and fibre solutions is expected to fetch a long-term return, hence, we have a dyed in the wool policy for quality testing. We are committed to use only the best material and always exceed customer's expectations in terms of standard.All our products areROHS compliant and manufactured under a great degree of supervision and stringent in-process inspection.

Each of the manufacturing and assembly units is ISO 9001:2015 and ISO 14001:2015 certified.Strict qualification and evaluation of designs, material and processing methods ensure guaranteed customer satisfaction. Once manufactured, the products are sent to the QA team where each and every technical specification is checked and tested in detail.

A robust corrective auto-system is in place with firm focus on verification for troubleshooting.

Sign up to our newsletter and be the first to know about latest news, special offers, events, and discounts.

© 2018 All Rights Reserved. Terms of Use and Privacy Policy